Big Sky Eng Lining Solutions

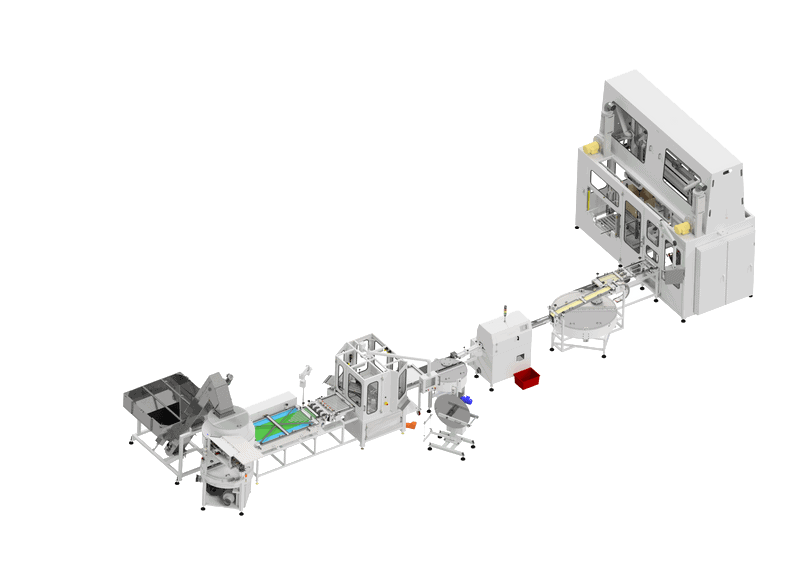

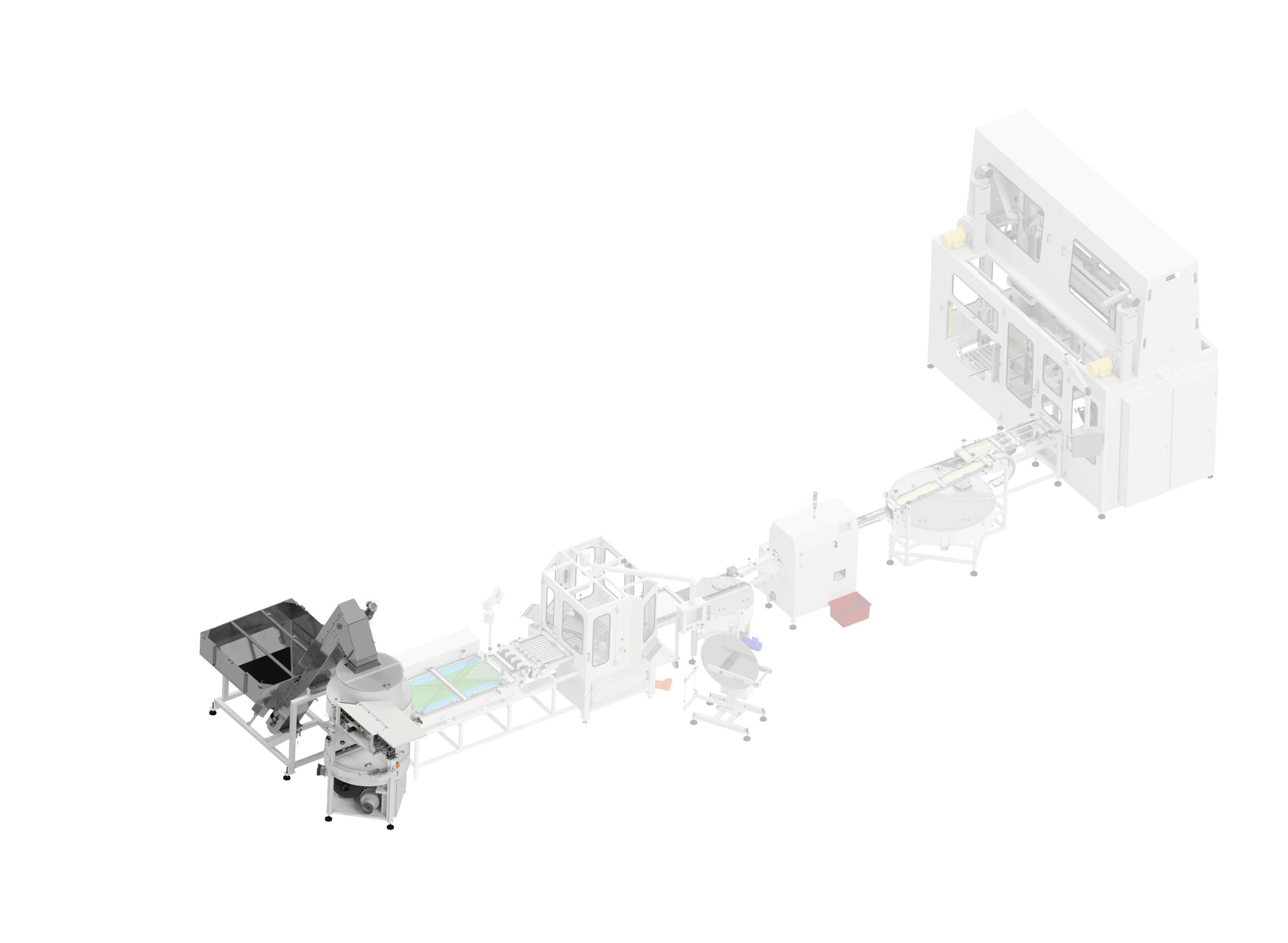

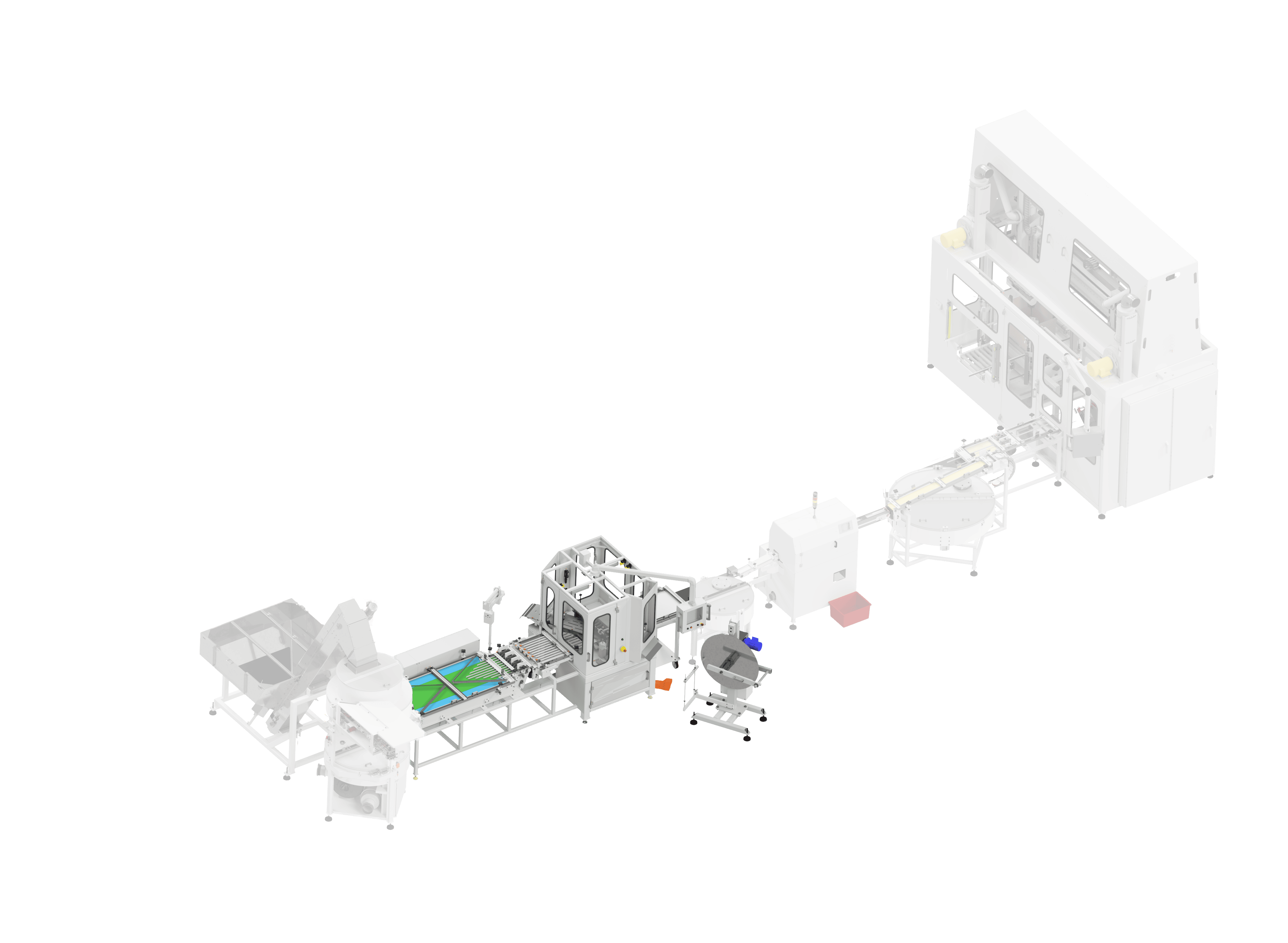

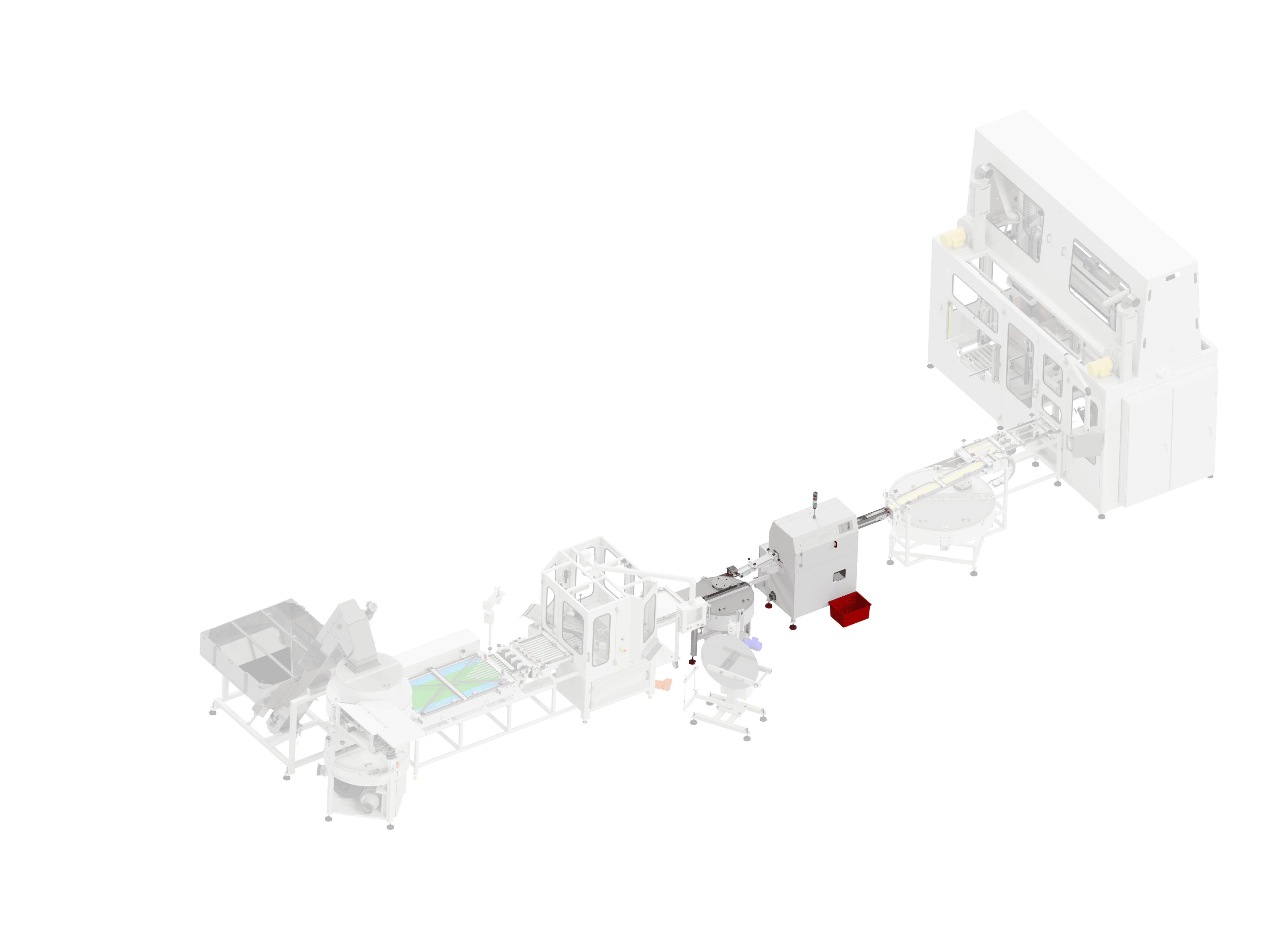

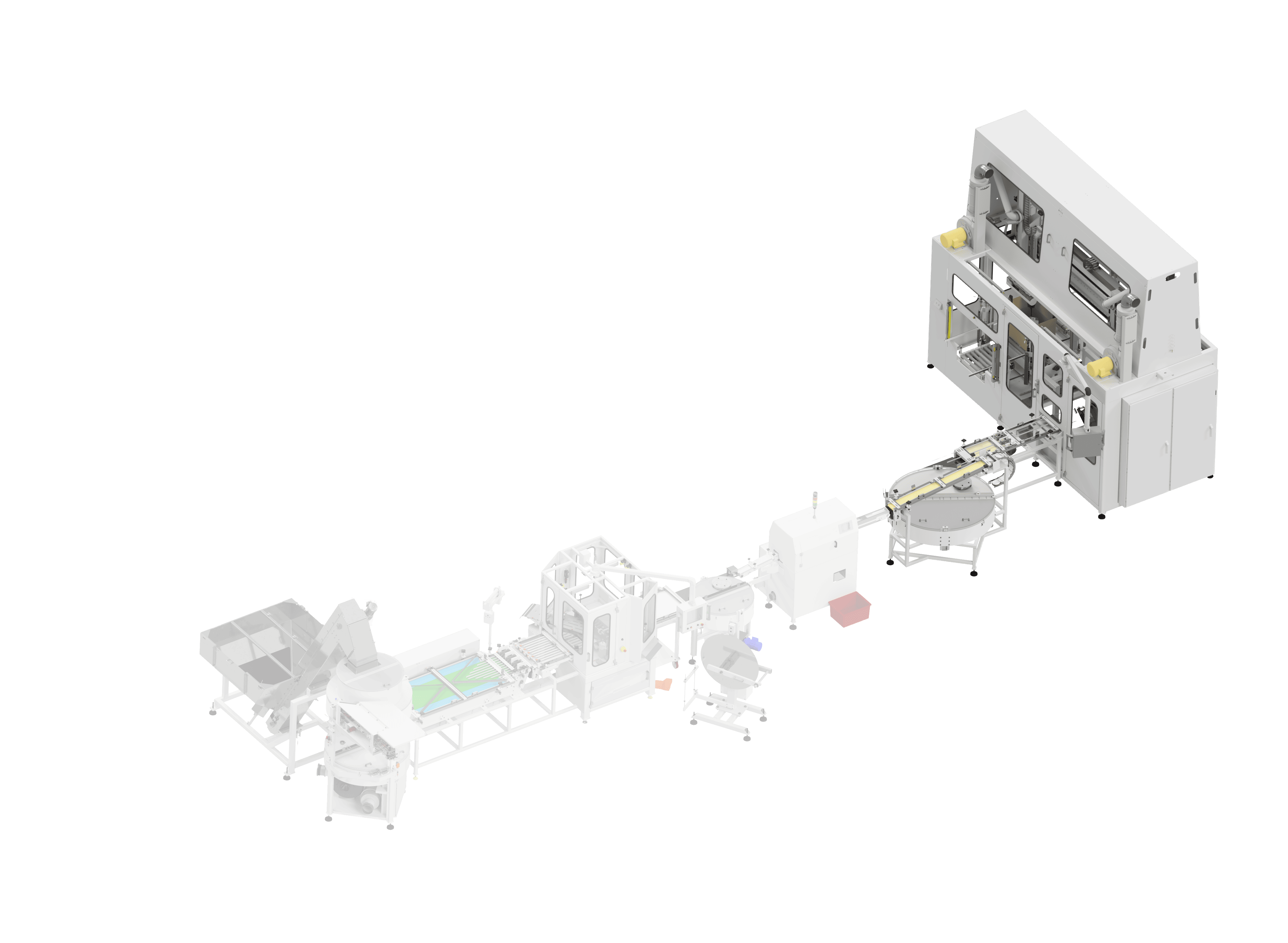

CLOSURE LINING & STACKING SOLUTIONS

Why work with us?

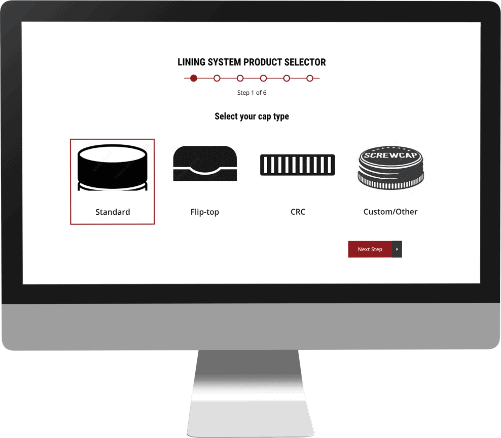

Big Sky Engineering is unique in having both broad experience in the design and development of custom automation equipment systems, plus in-depth knowledge of innovative closure lining machine production, lining material development, lining material supply chain management, strip-width consolidation / inventory reduction, and the streamlining of closure business operations.

Request a Quote

80

Energy savings of centrifugal

blowers vs. compressed air

blowers vs. compressed air

25

Material savings compared to

other stamping patterns

other stamping patterns

5

More caps lined per cycle than

traditional rotary lining machines

traditional rotary lining machines

SERVICE & SUPPORT

SERVICE

Technical supports commitment to timely solutions. If we cannot resolve a performance issue in the first service visit, expect us to return with engineering support to collaboratively find or design a successful fix.

Learn More

PARTS

If you need emergency parts, want to restock your spare parts kits, require assistance with identifying a part or simply want a new manual, our team is only a call or email away. We maintain an inventory of quality-approved spare parts and consumables, can help identify replacement parts for obsoleted items and are happy to expedite your order if you are in a pinch.

Learn More

REMOTE SERVICES

Remote service support is not a second-class speculation or over-the-phone symptom checker anymore. Nor is it a security concern. Technology has elevated remote service support to preferential status. It enables us to help you troubleshoot your automated equipment immediately instead of organizing a service technician to fly out and visit your manufacturing facility.

Learn More

MAINTENANCE SERVICE CONTRACTS

Our company specializes in maintenance contracts for automated machines, providing proactive servicing and support to ensure optimal performance and minimal downtime. With our tailored agreements, you can rely on scheduled inspections, timely repairs, and expert troubleshooting to keep your operations running smoothly. Trust our dedicated team to safeguard your equipment's longevity and efficiency, allowing you to focus on maximizing productivity and profitability.

Learn More

SERVICE & SUPPORT

SERVICE

Technical supports commitment to timely solutions. If we cannot resolve a performance issue in the first service visit, expect us to return with engineering support to collaboratively find or design a successful fix.

Learn More

PARTS

If you need emergency parts, want to restock your spare parts kits, require assistance with identifying a part or simply want a new manual, our team is only a call or email away. We maintain an inventory of quality-approved spare parts and consumables, can help identify replacement parts for obsoleted items and are happy to expedite your order if you are in a pinch.

Learn More

REMOTE SERVICES

Remote service support is not a second-class speculation or over-the-phone symptom checker anymore. Nor is it a security concern. Technology has elevated remote service support to preferential status. It enables us to help you troubleshoot your automated equipment immediately instead of organizing a service technician to fly out and visit your manufacturing facility.

Learn More

MAINTENANCE SERVICE CONTRACTS

Our company specializes in maintenance contracts for automated machines, providing proactive servicing and support to ensure optimal performance and minimal downtime. With our tailored agreements, you can rely on scheduled inspections, timely repairs, and expert troubleshooting to keep your operations running smoothly. Trust our dedicated team to safeguard your equipment's longevity and efficiency, allowing you to focus on maximizing productivity and profitability.

Learn More